P300

P300 in action. Speed is app. 30km/h. Photo: Teppo Mäkelä

Roll out 2.6.2012 at Joensuu Finland.

More pics here | Project blog here in Finnish | Project blog translated Finnish to English by Google

NEW: Construction plan in full 1:1 scale - in PDF format.

Construction of the front part

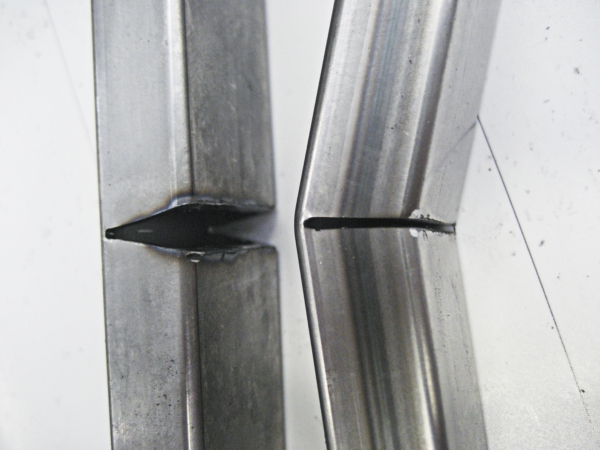

The boom tube is a 40x40-1.5mm thick welded to 30x15-1.5mm "loop" fork parts.

How to bend fork parts.

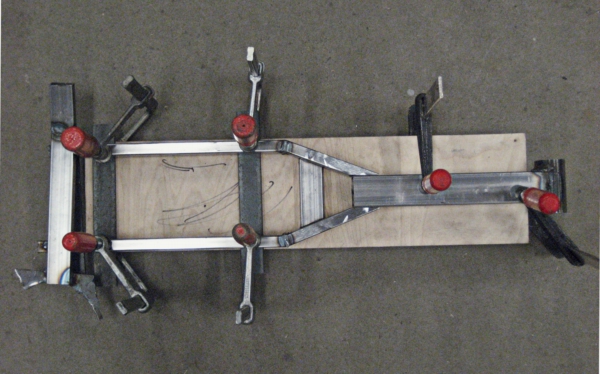

All fork parts together in welding assembly plywood.

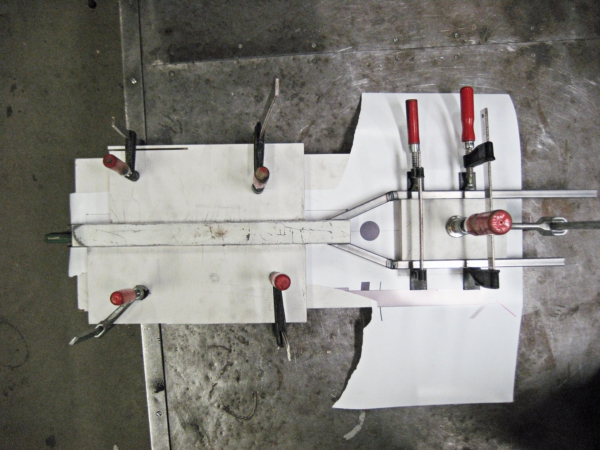

Nose boom welding assembly.

Front part - nose boom to fork pieces welding assembly.

Last joint - front part - pivot/nose boom together in 20 degree bend. Dropouts comes over this joint.

Construction of the rear part

The bottom tube is a 40x40-1.5mm thick welded to 30x15-1.5mm fork parts - in this pic, parts are tighten to plywood plate.

Pivot

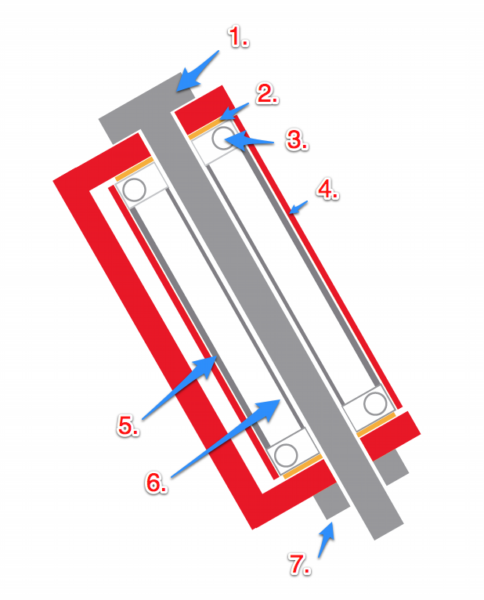

Pivot idea illustration (60 degree angle):

1. 12mm bolt 2. Washer (hits only bearings center) 3. Bearing - sealed (12mm inside hole - 32mm outer diameter - 10mm thick) 4. Tube 100mm - 32mm inside diameter 5. Tube 78mm - 32 mm outside diameter tube (hits only bearing outer part) 6. Tube 80mm - supports bolt - a bit longer than tube what makes bearing hole 7. Nylon lock nut

Rear part grab, before welding.

Statistics

| Pivot Angle [°] | Trail [cm] | Seat Height [cm] | BB-Seat Diff. [cm] | Ground Clearance [cm] | Wheelbase [cm] | Weight [kg] | BB-FWA [cm] | BB-EOS [cm] | Turning Circle [m] | Front Tubing [mm] | Wheel Size [inch] | CG [%] | |

| P300 | 59 | -14 | 35 | 20 | 18 | 108 | 14 | 47 | 75 | - | 30x15x1.5 | 20" 20" | - |