3D-Printing and CNC-Milling

On 2011-04-29 Dirk Bonné posted a great and visionary idea in the Python Mailinglist. The actual follow-up discussion starts here:

A week ago I came across the reprap project (reprap.org), which is an "open source" 3D printing machine. Such a printer can print pieces of plastic, supposedly in any form as long at it is limited in size. I'm very much tempted making such a machine for my self (as winter project).

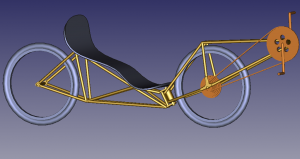

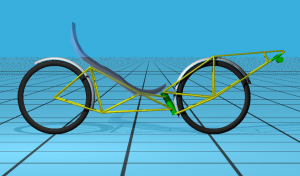

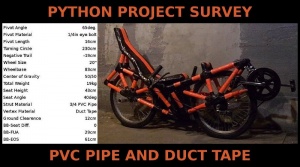

One idea I have is to build a bike (e.g. python) using the reprap. The goal would be to build a trellis-framed python, like my own bike (pythoon) and some others seen on the project page. I would still use regular steel tubing with small diameter (8-16mm), but the joints connecting those tubes would be printed plastic bits that are pressed inside of the tube. The construction process would look like this:

- design all the joints connecting the tubes.

- print them -> results in "inner lugs".

- cut the metal tubes to the right length (tube cutter).

- assemble the frame by pressing the plastic joints in the tubes.

=> at this point I would like that the bike is stiff enough to hold itself.

The next phase would strengthen the bike by wrapping uni-directional carbon fiber around the joints (like using a tape roll wrapping it around forming a "outer lug":

- paint the tubes with a primer before wrapping the CF around

- cut the roll of unidirectional CF in long strands about 1 cm width

- use a brush dipping the CF with epoxy while wrapping it around the joints firmly connecting the tubes to the joints.

What I hope the advantages would be:

- sharing: possible to share the design between people - anybody with a 3d-printer could produce a bike. It would even be possible to make a program that given some parameters can produce a custom measurements.

- easier/quicklier: the tubes are just cu wih a plain tube cutter tool. There is much less measuring and filing involved (making a trellis frame can really be horrible - especially when brazing where precision means all).

- easier: no need for a jig. The joints would make the frame pre-stiff enough to easily adjust the frame as a whole using a measuring stick.

- equipement: no welding/brazing equipement needed (ok, you need a 3d printer....).

Other directions: the same process would be useful for a pure CF-bike or may be a bamboo-bike...

What is your take on the idea? Is there ny around iwth experience with 3d printing product?. Could it work? Would there be a real advantage?

DirkB

PS: with the reprap I discovered there is a 3D CAD for programmers: OpenSCAD. For those with the programming ability, it might be alternative for autocad and the like.

DirkS: Based on recent mailing list discussion and my thoughts: We could use the Moulton idea with an inner "rope" putting tension on the tubing from one joint to the next. This way, we could prevent/limit "bending forces" on the pastic joints by pulling them into the tubing. Maybe a rope could run across several joint and through the tubing to pull the whole frame or a section of it in one go. Maybe the joints could be designed in a modular fashion, that they are not a "three-way-piece" tighly fitting into the tube coming from three directions, but are one piece per tube end with a means to be interlocked with each other in a way to allow for different angles between the tubes. The stiffness of the frame results only from the use of diagonal tubes, pulled together by the rope or string. Or the joints are of the multidirectional type, but each end towards a tube is not a tight fit, but rather a "ball", such that the tubes can be adjusted for a certain range in angle.